Custom Machined Seals

Machined Seals for Hydraulic Cylinders

Small or Large Runs

We can machine 1 piece or 100 pieces. No job is too small or big.

Certificate of Conformance

Certificate of Conformance is available upon request.

Expedites

Expedites are available to accommodate rush jobs.

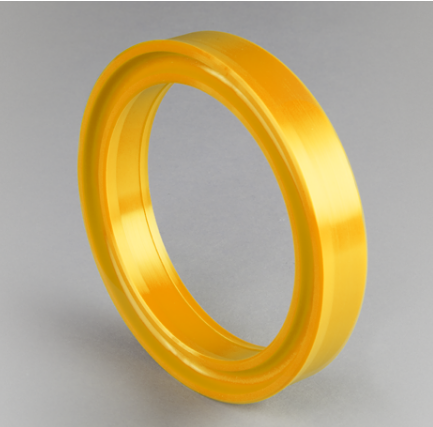

WIPERS, BACKUP ringS, ROD SEALS, PISTON SEALS, WEAR BANDS, ROTARY SEALS, VEE SETS, o-rings, AND MORE!

CRC machines custom seals in-house with dimensional capacities up to 24 inches in diameter. We can offer sizes up to 57 inches in diameter through our supplier partners. Choose from a selection of pre-designed seal profiles or provide your own seal drawing. We will machine your seal according to the steel dimensions provided. We have a wide range of seal materials in stock including polyurethane, NBR, HNBR, Viton, bronze-filled Teflon, virgin Teflon, polyacetal, and nylon.

Seal Materials

94 AU 30000

Offers a significantly longer service life and has a wide temperature range of -35 °C and 120 °C. High tear resistance boosts operating life and resistance to wear. High extrusion stability allows operating pressures up to

50MPa/500 bar. Excellent compatibility with mineral fluids (no shrinkage/swell).

BRONZE-FILLED PTFE

Improved compression strength, thermal conductivity and electrical conductivity. It also has a reduced extrusion tendancies while maintaining good sliding and wear properties. Bronze-filled PTFE is the standard material in hydraulic applications.The ratio is 40 % bronze + 60 % virgin PTFE.

C-HPU 57

C-HPU 57 is an all-purpose, casted, hydrolysis resistant sealing material. This material is characterized by its excellent mechanical properties. The lower friction is especially helpful in many applications. Can be used in high pressure applications. Temperature range from -22 F° to 230 F°.

.png)

C-HPU 96

C-HPU 96 shore A is an all-purpose, casted, and hydrolysis resistant sealing material. This material is characterized by its excellent mechanical properties. It is also FDA compliant. Temperature range from -35 F° to 230 F°.

EPDM

EPDM has very good low temperature properties, high resistance to ozone, aging and weathering, as well as polar solvents (alcohols, ketones, esters) and HFC liquids and Glycol-based brake fluids. Not resistant to petroleum products, fats and oils.

FPM BLACK

This black colored FPM material is slightly harder than the brown FPM. FPM has a high chemical resistance and is suitable at high temperatures. But it loses the elasticity at moderate low temperatures. Temperature range is from -4 °F to 410 °F.

FPM BROWN

FPM has a high chemical resistance and is suitable at high temperatures. But it loses the elasticity at moderate low temperatures. Temperature range is from -4 °F to 428 °F.

Example of applications include: lip seals, seals for offshore applications, direct contact with fuel, rotary seals at high velocity.

GLASS-FILLED PTFE

PTFE I with a hardness of 58 shore D, compounds of 15 % clean milled glass fibres + 5% MoS2 + 80 % virgin PTFE. It has good strength and reduced cold flow, both at high and low temperatures. It offers improved wear and friction behaviour. Suitable for seals in hydraulic applications with low to middle pressure values.

HPU 55D

Hydrolysis resistant polyurethane is a universally applicable sealing material with a wide service temperature range, easy installation, and high pressure resistance. HPU 55D is often used as axial face seal in piston and rod seals. Easy installation and high pressure resistance characterizes this grade of HPU.

HPU 95

HPU 95 Shore A is a universally applicable sealing material which can be characterized by its wide service temperature range. It has a very low compression set, excellent wear resistance, high elasticity, high dynamic resistance as well as low permeability. Temperature range from -4 F° to 240F°.

H-NBR

H-NBR has improved abrasion resistance and retains high elasticity. Temperature range is from -4 °F to 302° F. Resistant against non-polar and low-polar media, mineral oils, aliphatic hydrocarbons, and HFA-, HFB-, HFC-liquids. Also well-suited for use in water, diluted inorganic acids, and alkalis.

HYTREL 5555HS

Hytrel has good aging properties at high temperatures. It combines good resilience, temperature and chemical resistance with strength and durability. Hytrel can be used as sealing elements such as wipers, back-up rings and road seals pre-loaded with elastomer o-rings.

MVQ

MVQ (silicone) has a high resistance to low and high temperatures. The temperature range is from -76 °F up to 392 °F and short term up to 572 °F. Silicone is often used in the food industry. A disadvantage is the low resistance against oil and greases.

NBR 85

NBR has a service temperature range from -22 °F to 230 °F. It hardens at higher temperatures. NBR is not suitable for uses in solvents and difficult flammable hydraulic fluids. It has very good elastic properties and high extrusion strength.

PA

Polyamide has high strength, stiffness, and hardness. Excellent wear resistance, sliding properties, and good temperature resistance. PA is a high-quality, yet inexpensive plastic for sliding applications in mechanical engineering. Temperature range from -40 °F to 230 °F.

POM

Polyacetal has good mechanical strength and very good dimensional stability for precision parts. High rigidity and strength result in minor deformation even at higher temperatures. Excellent wear resistance, turning properties, and sliding properties.

UHMW-PE

Ultra-high molecular weight polyethylene has high resistance to abrasive wear, very good impact behavior, and is resistant to oxidation. UHMW-PE is especially suitable for water hydraulics and ceramic coatings. It is generally recognized as safe for foodstuff applications.

PTFE CARBON

Contains 75% PTFE and 25% carbon fillers. It has a hardness of 67 Shore D. The carbon fillers improve the creep resistance, hardness, and thermal conductivity of the PTFE. This material offers excellent wear properties and is particularly suitable for use in water. It is a standard material for hydraulic seals.

More Seal Materials Are Available

We keep a large selection of sealing materials in stock. Other materials can be sourced for your application.

Elastomers

- NBR 85

- NBR Soft

- NBR 85 White

- H-NBR 85

- H-NBR 90

- H-NBR 87 ED

- T-NBR 80

- EPDM 85

- EPDM 82 FDA

- EPDM FDA

- EPDM 81 KTW/FDA

- Silicone 85

- Silicone 85 Natural FDA

- Silicone 85 White FDA

- FPM 82 Brown

- FPM 85 FDA

- FPM 85 Black

- FPM 85 ED

- FEPM 85 AFLAS

Polyurethanes

- HPU 95A

- HPU 55D

- C-HPU 57D

- C-HPU 72D

- LT-PU PLUS 96A

- SL-PU 96A

- PU 93A

PTFE

- PTFE Bronze 40%

- PTFE Carbon-Graphite 13/2

- PTFE Carbon-Graphite 23/2

- PTFE Glass-Moly 15/5

- PTFE Virgin

Thermoplastics

- POM

- POM Black

- Nylon 6PA

- UHMW-PE

- Hytrel

- Peek

MATERIAL COMPATIBILITY

Click below for a complete list of sealing materials and their compatibility.

What happens after we receive your custom seal order?

The batch & cure information is recorded from the raw material that was selected for the seal. The dimensions are then loaded into the DMH program and sent to the Haas ST30 to be machined. After the part is finished, it is measured with calipers and the VMS (Video Measurement System) for tolerances.

Past Projects

We have machined custom seals for many different applications and operating parameters. Please Contact Us if you have questions about materials or profiles.

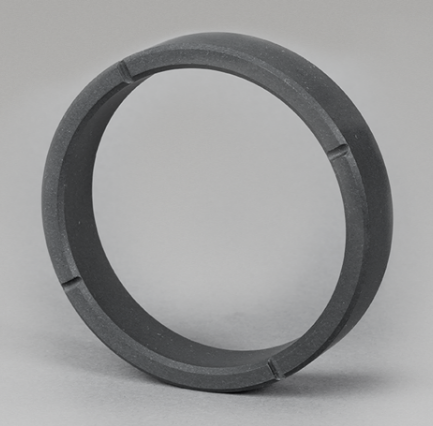

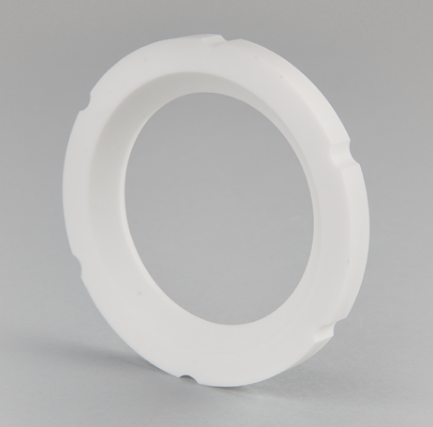

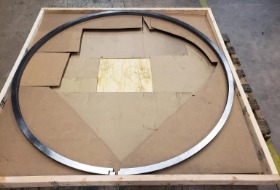

Cast Iron Piston Ring

73-inch diameter custom machined cast iron piston ring.

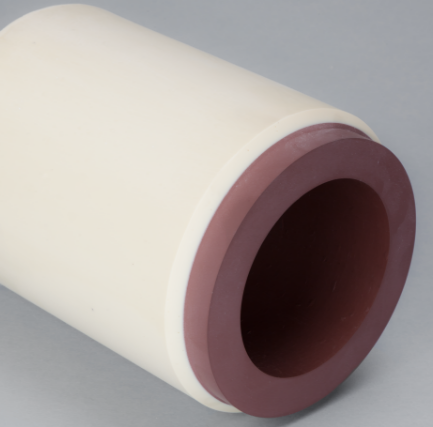

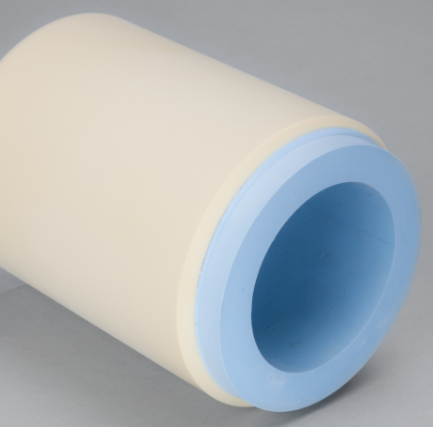

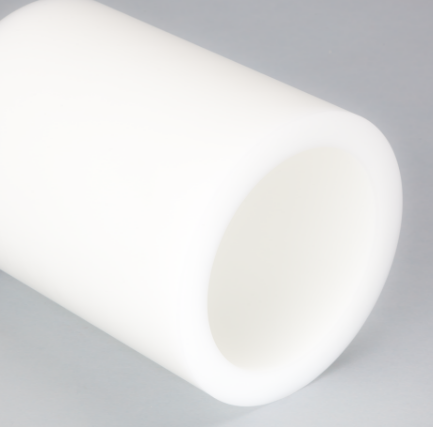

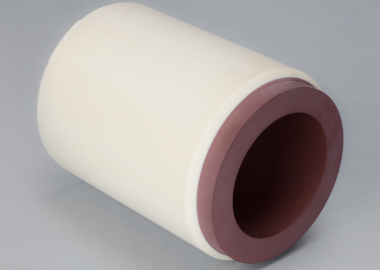

Bronze-filled Teflon Piston Seal

Custom 2-piece piston seal machined from bronze-filled Teflon plus NBR energizer.

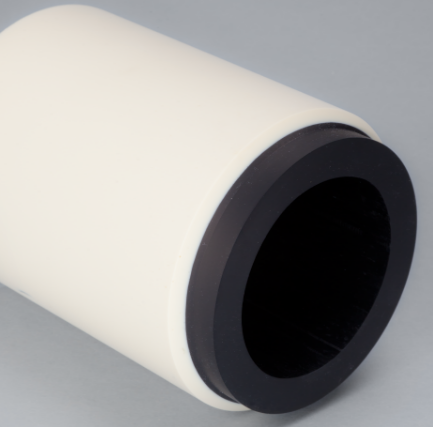

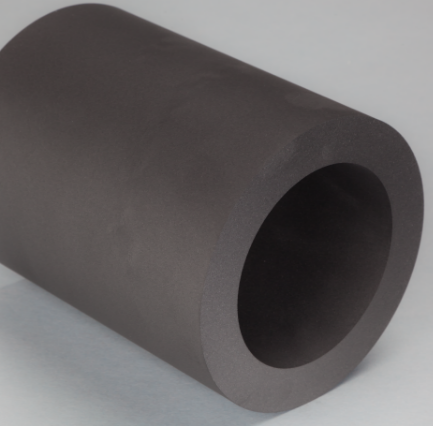

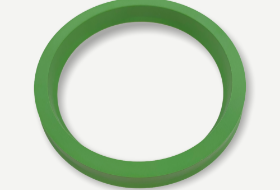

HNBR Rod Seal

Custom machined rod seal from HNBR for high-temperature cylinder applications.