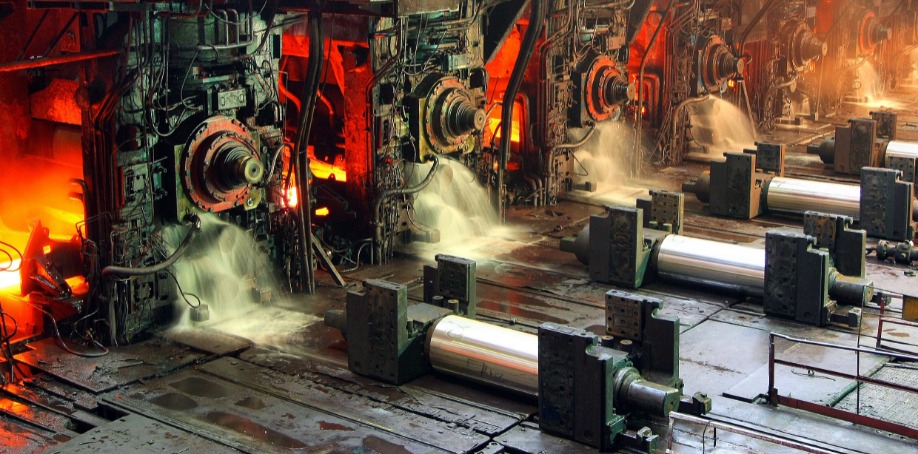

Steel Mill Products & Services

Customized Seal Kits

We will work together with the steel mill's engineering and maintenance departments to design the optimal sealing solution for mill-type cylinders operating in high temperatures.

.jpg)

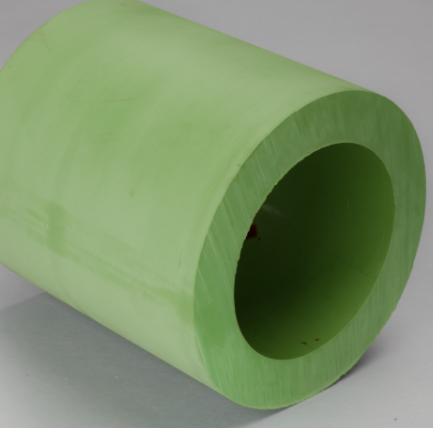

Hallite Wear Bands

Manufactured to very tight tolerances, the Hallite 506 is capable of withstanding extreme side loads and preventing metal-to-metal contact.

The Hallite 506 is available in three forms: pre-cut bearing rings, spiral lengths, and flat coils. Spiral lengths and flat coils are recommended to customers who want to cut their own custom sizes.

.jpg)

H-NBR materials

H-NBR has improved abrasion resistance while still retains high elasticity. Its service temperature range is from -20°C to 150°C. It also works for a short time in hot air up to 180°C.

It is resistant against non-polar and low-polar media (vegetable and animal fats) and in particular, mineral oils (lubricating oils, hydraulic oils or fuels), aliphatic hydrocarbons, and HFA-, HFB-, HFC-liquids. H-NBR is also well-suited for use in water, diluted inorganic acids, and alkalis.

The material is not resistant to aromatic and polar solvents, concentrated acids, and alkalis.

Large-diameter oil seals

Radial oil seals generally consist of a flexible rubber lip bonded to a rigid metal case. Most also contain a third element - a garter spring - fitted into the rubber lip to provide additional sealing force, both initially and over the life of the seal.

The total radial force of the sealing lip is a function of the rubber pre-tension, coupled with the tensile spring force. The sealing lip may be lathe cut or ready molded and may feature molded-in hydrodynamic aids to assist sealing in demanding applications.

The metal case may be exposed or have rubber molded around it for ease of assembly or improved static sealing.