Orkot® Hydro Bearings

Tubes, sheets, custom shapes

Orkot® is offered in tube, sheet, or custom shapes. Standard tubes are 24 inches long and available in a variety of wall thicknesses. Standard sheets are 24 inches x 48 inches, with larger sizes available. Sheets can be produced up to 6 inches thick or bonded for custom designs. CRC can provide finished parts, raw tubes, or raw sheets.

Best Features

format_color_reset

Dimensionally Stable

Virtually 0% swell in water.

public

Environmentally Friendly

Water-lubricated bearings or can run dry without the need for external lubricants.

Easy Installation

Freeze fit, press-fit, bonding, or mechanically fastened. Can be freeze fitted without danger of shattering.

history

Exceptional Wear Resistance

Tolerant to edge loading and misalignment.

Easily Machined

As a general guide, methods used for brass, aluminum, or lignum vitae will apply to Orkot® materials.

Low Friction

Specialized low friction bearing surface to extend dry running capabilities and further reduce friction and wear rates.

How is Orkot® Manufactured?

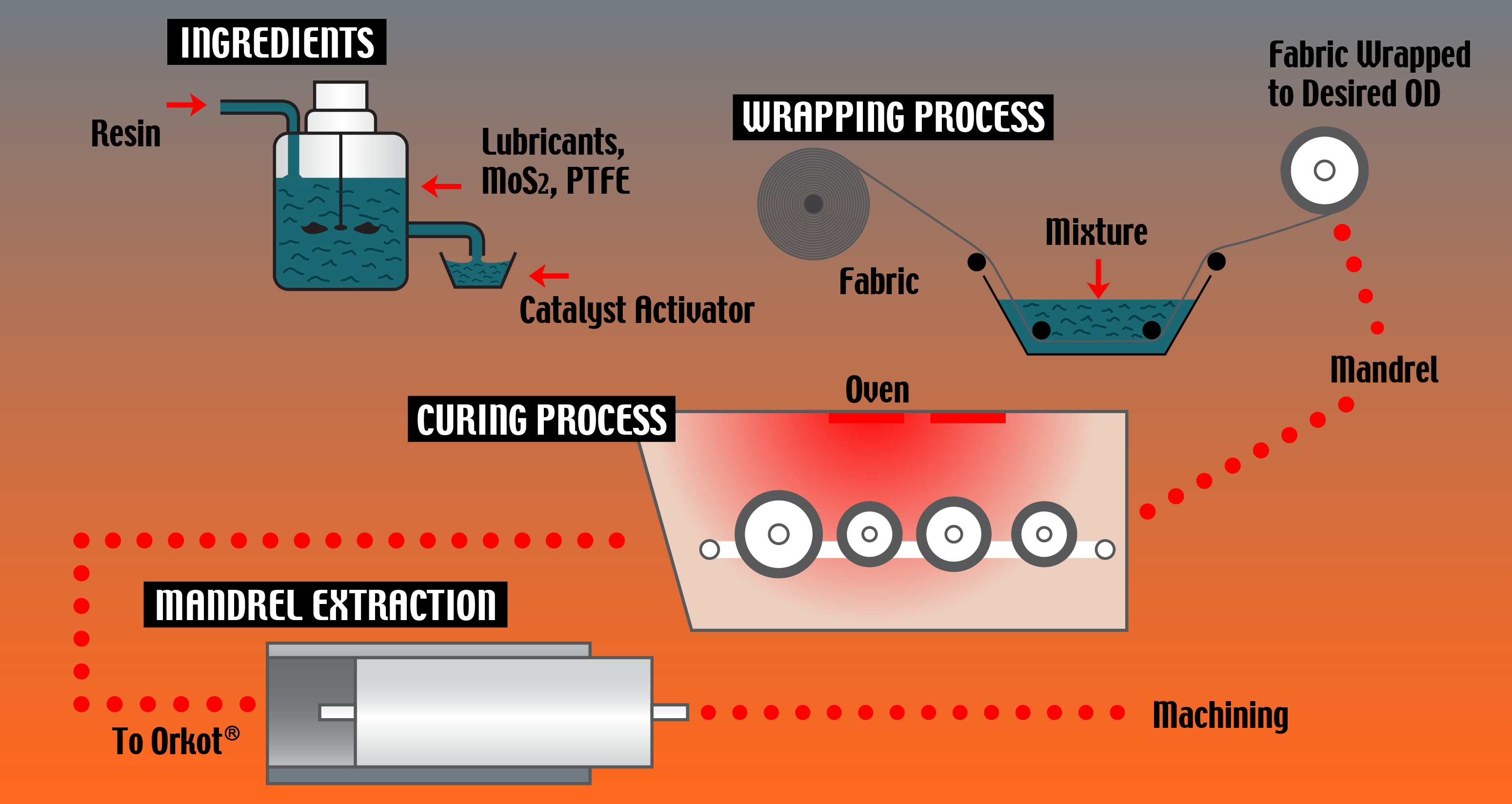

The drawing below illustrates how Orkot® thermoset composite materials are made. The manufacturing process incorporates a woven fabric and solid lubricants within a thermosetting resin matrix.

TESTED AT POWERTECH LABS AND APPROVED BY THE US ARMY CORPS OF ENGINEERS FOR USE IN HYDRO APPLICATIONS.

Top - Tactical outage plan

It's okay if you don't know the housing ID until the line boring operation is complete. We have a TOP (Tactical Outage Plan) for hydroelectric overhaul projects working with limited dimensional information. The TOP stages oversized bushings on-site or at CRC's location. The staging allows the material to be machined much faster which gets the turbine back into service quicker. The TOP process is deliberate and allows CRC to accelerate delivery without risk to quality, safety, or asset integrity.

Step1

The client provides the time frame the project requires and theoretical dimensions for bushings. CRC quotes oversized bushings.

Step 2

Rough cut, oversized bushings are ordered, mobilized, and staged at CRC or the client's job site.

Step 3

Upon completion of line boring operation, the client provides new housing dimensions to CRC.

Step 4

CRC engages the Orkot® engineering department, and a calculation sheet is produced with final machined dimensions. The calculation sheet is sent to the client for approval.

Step 5

Upon receipt of approval, bushings are machined either by the client on-site or by CRC and shipped out within the time frame needed.

Step 6

Accelerated delivery and a predictable outcome.

Listen to an Orkot® Expert

Curious to know more? Listen to Tom Carew as he explains some advantages of Orkot® and talks about the manufacturing process at the 2019 HydroVision trade show.

Tom has been working with Orkot® for over 25 years and has solid experience working with hydroelectric projects.

Past projects

.jpg)