Wind Power Products & Services

Sealing Solutions for Wind Power

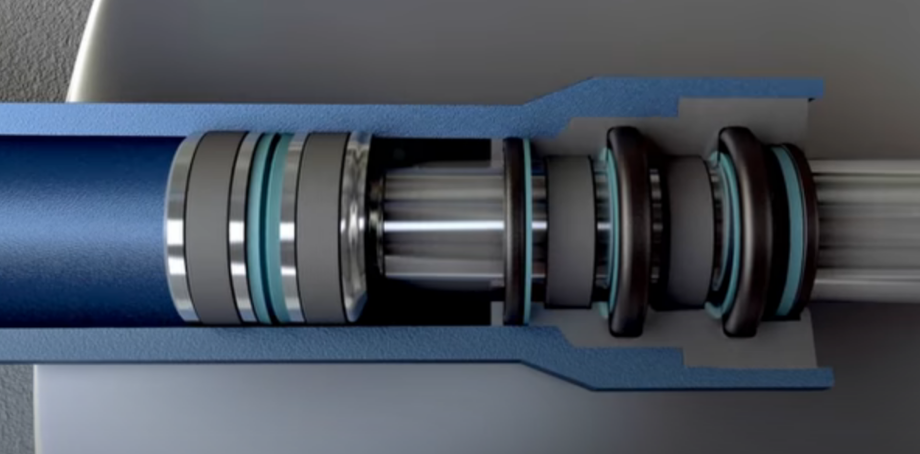

Seals for wind turbines need to provide low friction, long life, zero leakage, and easy installation, with maximized meantime between maintenance being a key requirement. Improve the efficiency of existing applications and lengthen maintenance intervals. Upgraded sealing solutions can contribute to decreased downtime and

increased yield.

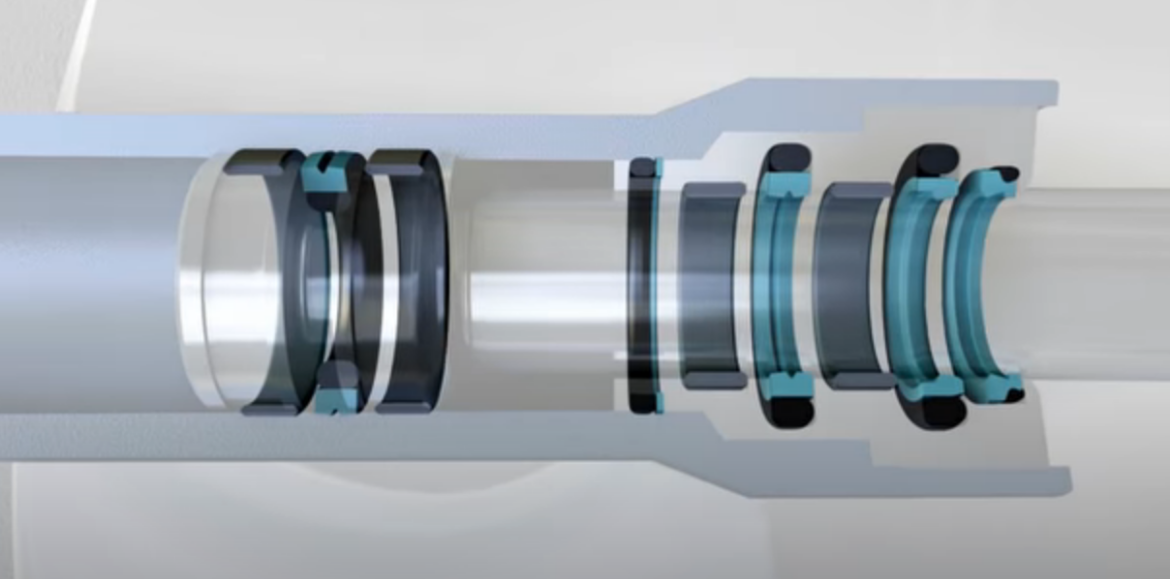

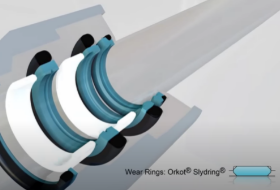

Orkot® Slydring®

Ideal for dry running situations and requires

no lubrication. Virtually zero swell in seawater. Dimensionally stable in arctic or tropical conditions. Tolerates both edge loading and misalignment.

Turcon® M12

Cost-effective material that provides extended seal life, as well as a wide operating window in terms of temperature, pressure, and velocity. It performs as well or better than other specialized compounds in each parameter.

V-Ring®

A unique all-rubber seal for rotary shafts that is suitable for a wide range of bearing types. The oil-side V-Ring® prevents oil from leaking out of the gearbox. The air-side V-Ring® prevents dust from damaging the gearbox.

Engineering Support from Trelleborg

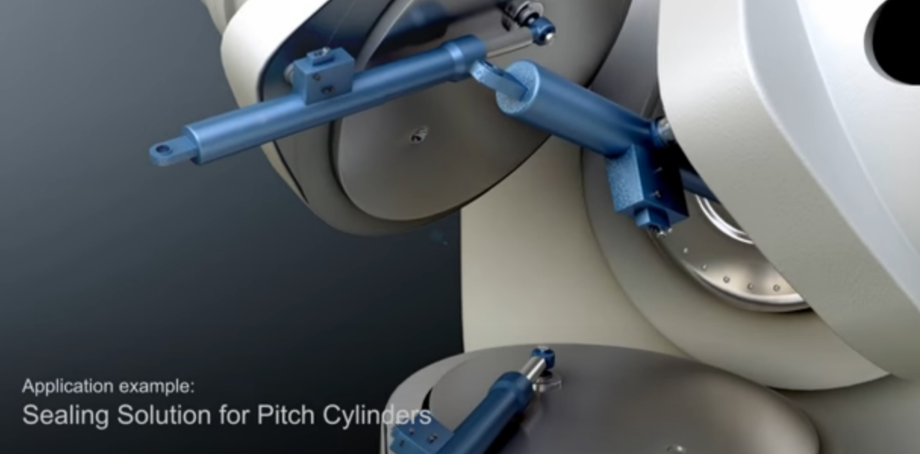

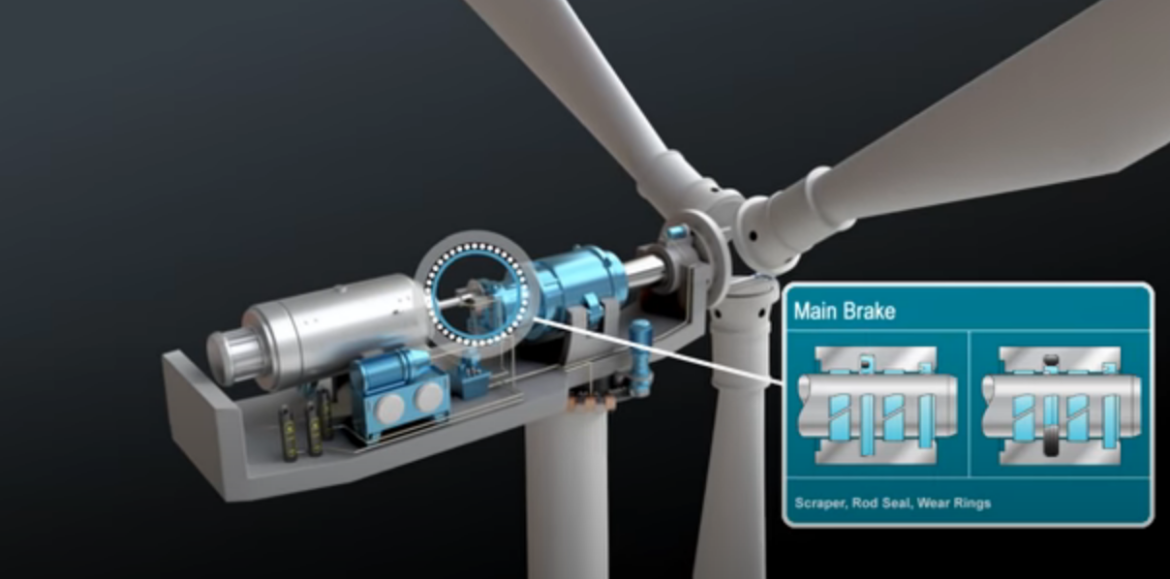

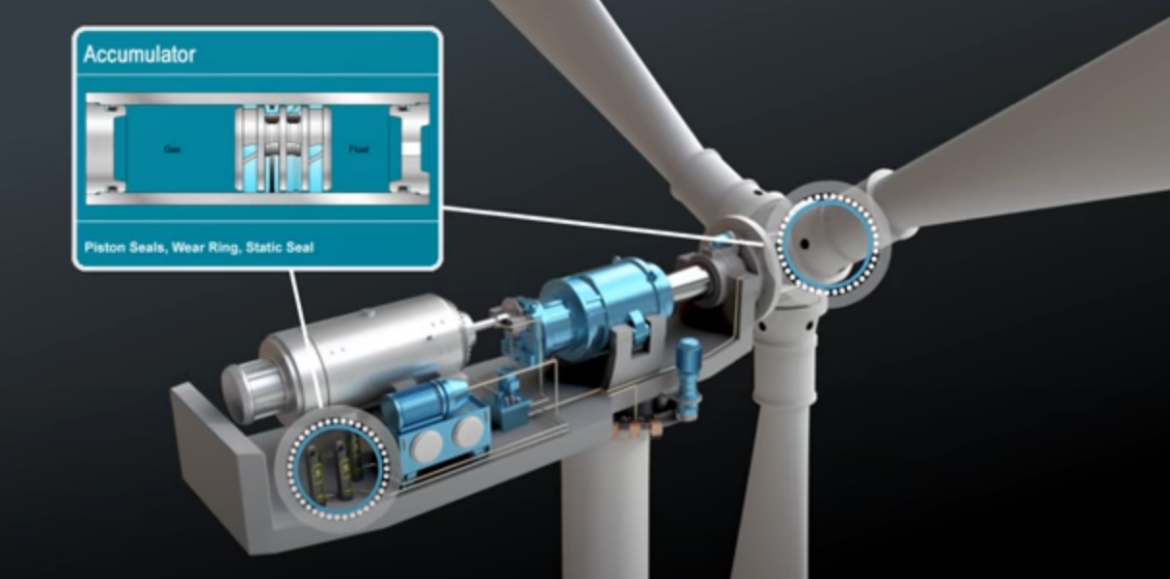

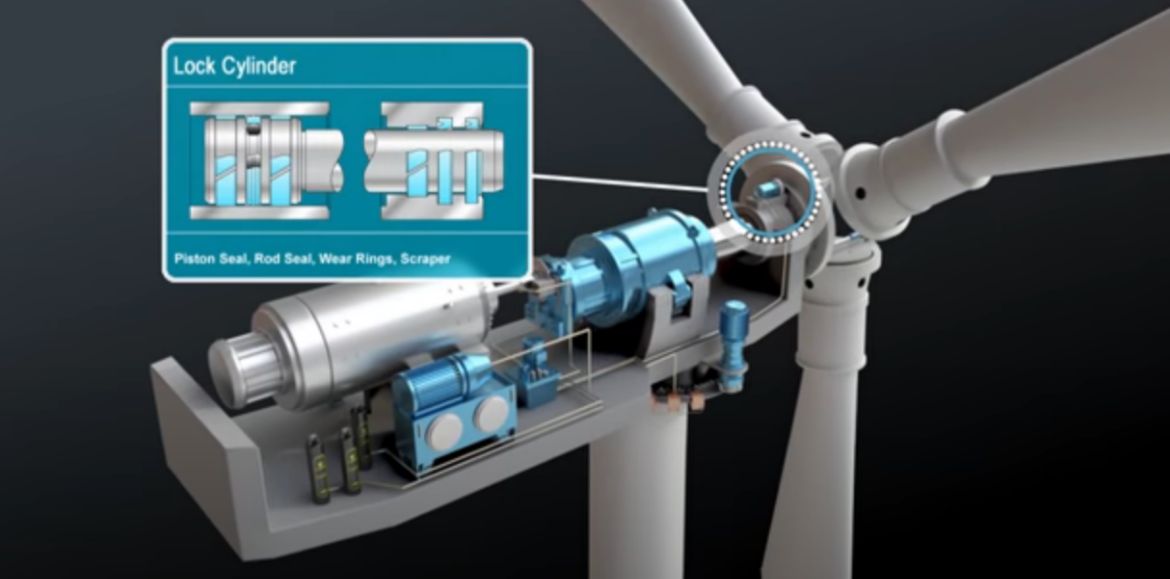

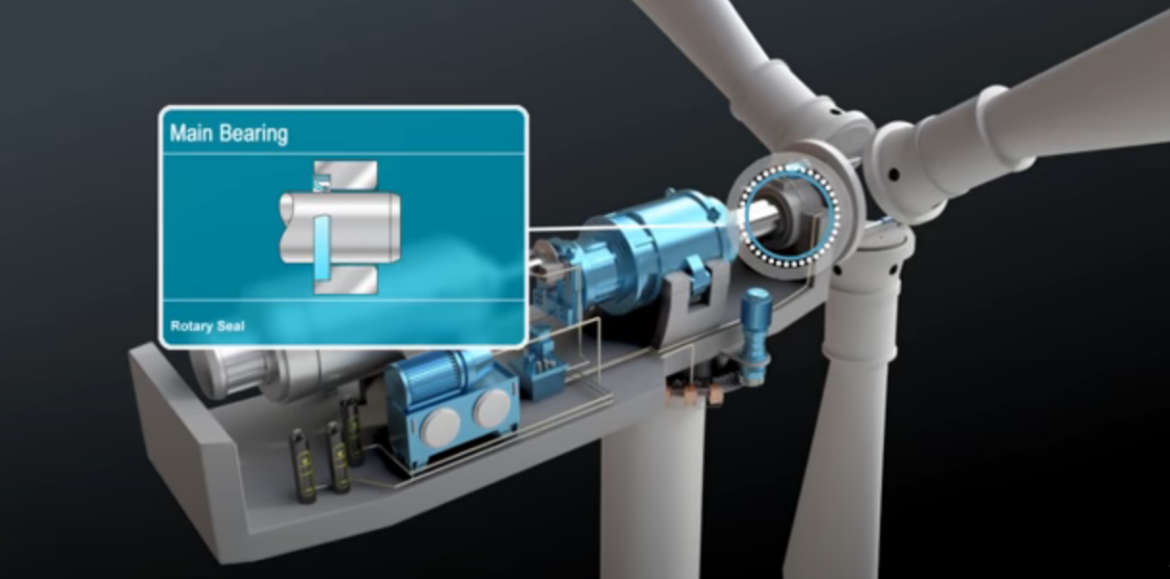

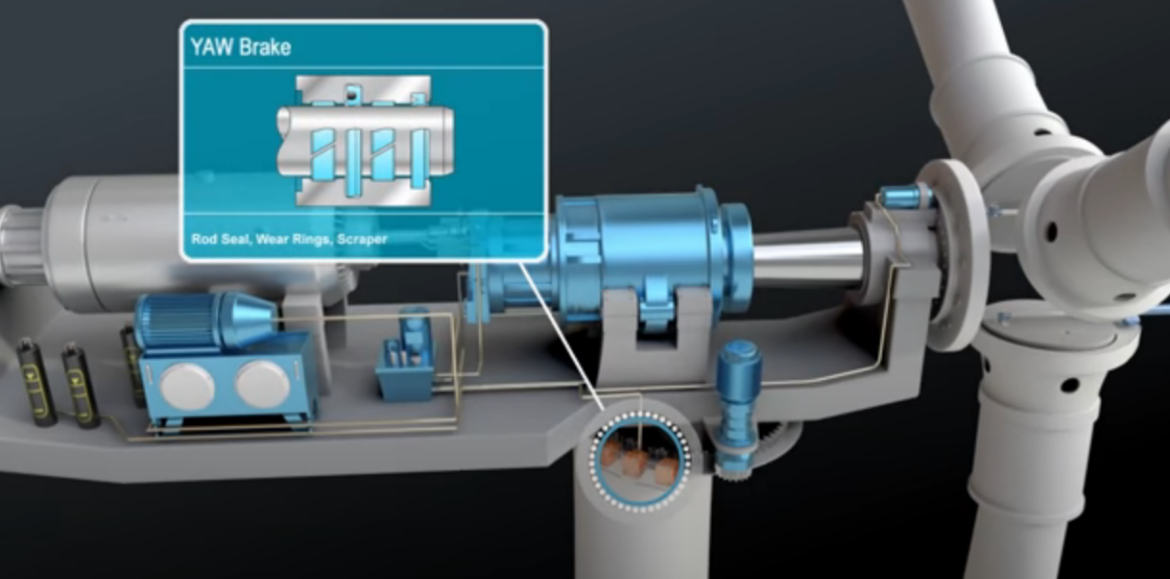

We work together with Trelleborg Sealing Solutions and OEMs, wind turbine re-manufacturers, or aftermarket wind power specialists to greatly improve the sealing performance in wind power applications, like:

- Pitch Cylinder

- Main Brake

- Main Gear

- Lock Cylinder

- Yaw Brake

- Accumulator

CRC's distribution expertise combined with Trelleborg's engineering support quickly optimizes sealing systems for wind turbines.

Our access to world-class engineering resources allows us to provide the right solution for virtually any sealing application. Using the latest Finite Element Analysis (FEA) techniques, we can rapidly go from the design stage to manufacturing.

ready to upgrade your sealing system?

Let's analyze your existing sealing system and optimize it. Contact us to get started.