Backups

Search in Category

Filter Your Search

Aftermarket Brand Equivalent

Aftermarket Brand Equivalent

Color

Color

Material

Material

Nominal Inner Diameter

Nominal Inner Diameter

Nominal Outer Diameter

Nominal Outer Diameter

Thickness

Thickness

Shop by Category

Back-ups

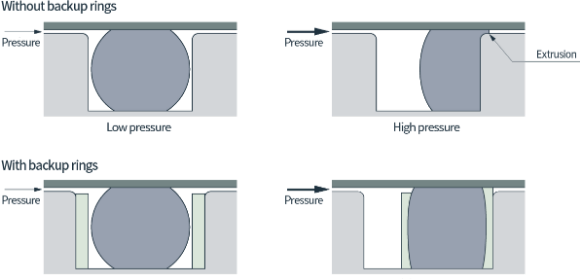

Back-up rings are installed together with o-rings or other accompanying seals to prevent gap extrusion in sealing applications. They are available in a spiral, split, or solid design.

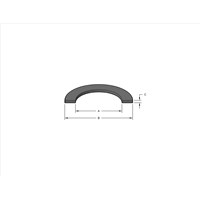

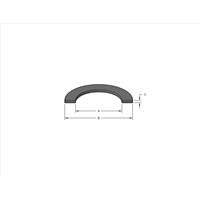

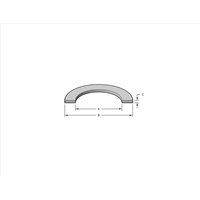

Parback® backup ring with a curved cross-section.

Parbaks are contoured on one face to minimize distortion of the o-ring when under pressure. Parbaks should be installed with the contoured face against the o-ring, but reversal does no harm.

90A Durometer | Buna-N Rubber Material | 4 1/8 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- Excellent extrusion resistance

- Easily stretched for installation

- Lubrication is enhanced by rubber which absorbs system fluid and does not plate out on rubbing surfaces

Parback® backup ring with a curved cross-section.

Parbaks are contoured on one face to minimize distortion of the o-ring when under pressure. Parbaks should be installed with the contoured face against the o-ring, but reversal does no harm.

90A Durometer | Buna-N Rubber Material | 1 3/4 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- Excellent extrusion resistance

- Easily stretched for installation

- Lubrication is enhanced by rubber which absorbs system fluid and does not plate out on rubbing surfaces

Parback® backup ring with a curved cross-section.

Parbaks are contoured on one face to minimize distortion of the o-ring when under pressure. Parbaks should be installed with the contoured face against the o-ring, but reversal does no harm.

90A Durometer | Buna-N Rubber Material | 2 3/4 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- Excellent extrusion resistance

- Easily stretched for installation

- Lubrication is enhanced by rubber which absorbs system fluid and does not plate out on rubbing surfaces

Parback® backup ring with a curved cross-section.

Parbaks are contoured on one face to minimize distortion of the o-ring when under pressure. Parbaks should be installed with the contoured face against the o-ring, but reversal does no harm.

90A Durometer | Buna-N Rubber Material | 3 3/4 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- Excellent extrusion resistance

- Easily stretched for installation

- Lubrication is enhanced by rubber which absorbs system fluid and does not plate out on rubbing surfaces

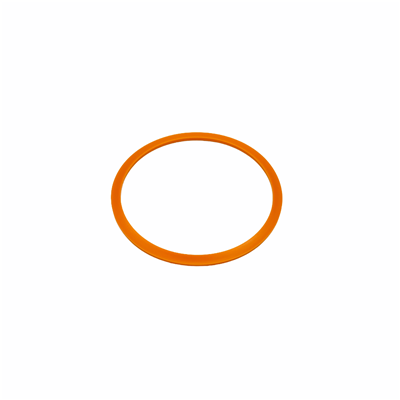

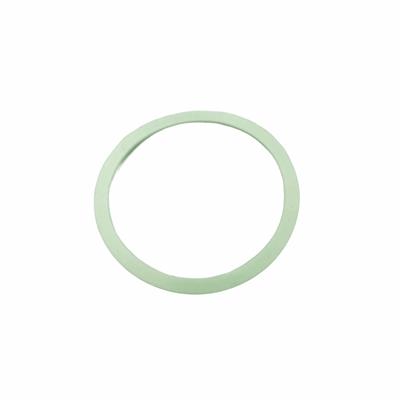

Solid Urethane backup ring with a flat cross-section.

95A Durometer | Urethane Material | 2 1/4 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- High strength and abrasion resistance

- Wide temperature range

- Chemical resistance

- Low friction

- Easy installation

Parback® backup ring with a curved cross-section.

Parbaks are contoured on one face to minimize distortion of the o-ring when under pressure. Parbaks should be installed with the contoured face against the o-ring, but reversal does no harm.

90A Durometer | Buna-N Rubber Material | 2 1/4 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- Excellent extrusion resistance

- Easily stretched for installation

- Lubrication is enhanced by rubber which absorbs system fluid and does not plate out on rubbing surfaces

Hytrel backup ring with a flat cross-section.

Molded of 55D Durometer Hytrel, these back-up rings provide excellent extrusion resistance and tolerance to fluids such as phosphate esters, hydraulic oil and water. Stretched for installation, they return quickly to their original size for easy installation.

55D Durometer | Hytrel Material | 2 1/4 in Nominal Inner Diameter | 0.11 in Cross Section | Backup Ring

Features

- Improved extrusion resistance compared to standard FKM or NBR backups

- Can be stretched over larger diameters and will return quickly to their original size

- High strength and abrasion resistance

- Wide temperature range

- Chemical resistance

- Low friction

- Easy installation

Parback® backup ring with a curved cross-section.

Parbaks are contoured on one face to minimize distortion of the o-ring when under pressure. Parbaks should be installed with the contoured face against the o-ring, but reversal does no harm.

90A Durometer | Buna-N Rubber Material | 2 1/2 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- Excellent extrusion resistance

- Easily stretched for installation

- Lubrication is enhanced by rubber which absorbs system fluid and does not plate out on rubbing surfaces

Solid Urethane backup ring with a flat cross-section.

95A Durometer | Urethane Material | 2 3/4 in Nominal Inner Diameter | 1/8 in Cross Section | Backup Ring

Features

- High strength and abrasion resistance

- Wide temperature range

- Chemical resistance

- Low friction

- Easy installation

Used primarily as an anti-extrusion device for u-seals, these back-up rings combine high performance with very low friction. “ST” suffix designates a split ring.

PTFE Material | 1 in Nominal Inner Diameter | Backup Ring

Features

- High strength and abrasion resistance

- Wide temperature range

- Chemical resistance

- Low friction

- Easy installation