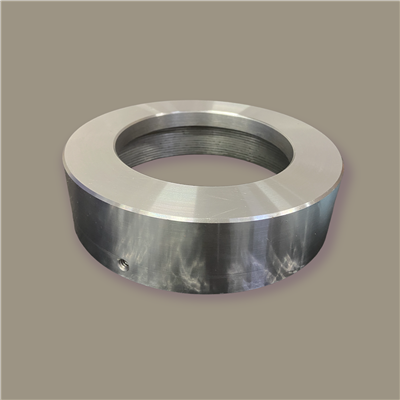

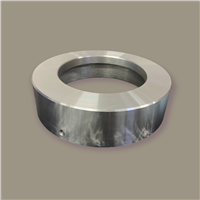

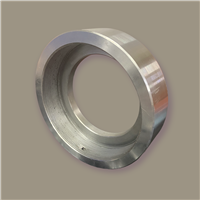

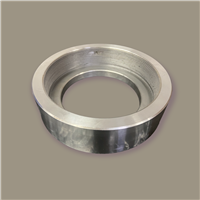

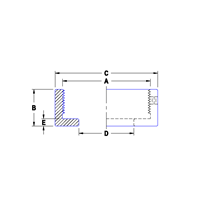

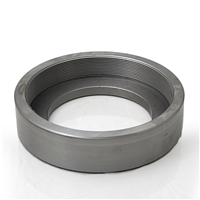

HC-5500-12 has a 6.5 in OD and is made to fit a 5 in bore cylinder.

Head cap size is determined based on the bending stress.

A static seal or o-ring is used in between the head cap and barrel (except welded construction).

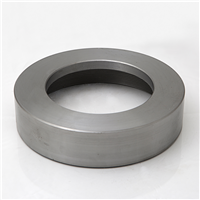

The main function of the head cap is to enclose the pressure chamber at one end. The cap is connected to the cylinder body by means of welding, threading, bolts, or tie rod.

CPO-2500 has a 2.5 in diameter with Standard Chrome. The base material is 1045 Carbon Steel with a yield strength of 75,000 psi.

ASTM A108 is the most commonly used and economical grade of shafting for hydraulic cylinder components, blower shafts, and mandrels.

- Extremely smooth surface finish

- Excellent wear and corrosion resistance

- Good strength and impact properties

- Good machinability

- Reasonable weldability

- Fair response to normal heat treating and induction hardening practices

Packages longer than 44 inches may have additional freight charges.

| 1-29 | $10.00 |

| 30-74 | $7.15 |

| 75-134 | $5.55 |

| 135-287 | $5.00 |

| 288+ | $4.55 |

2.5 in induction hardened chrome shafting. The base material is 1045/1050 Carbon Steel with 0.0005 in (0.0127mm minimum)-thick chrome plating and a case depth of 0.05 in (1.27 mm).

Induction Hardened Chrome is typically used in abrasive envrionments where the cylinder is exposed to rocks or heavy debris. Also used to machine clevis pins.

- Greater strength

- Better resistance to mechanical damage

Packages longer than 44 inches may have additional freight charges.

| 1-29 | $11.12 |

| 30-74 | $7.95 |

| 75-134 | $6.17 |

| 135-287 | $5.56 |

| 288+ | $5.06 |